PRODUCT RANGE

TECHNOLOGIES

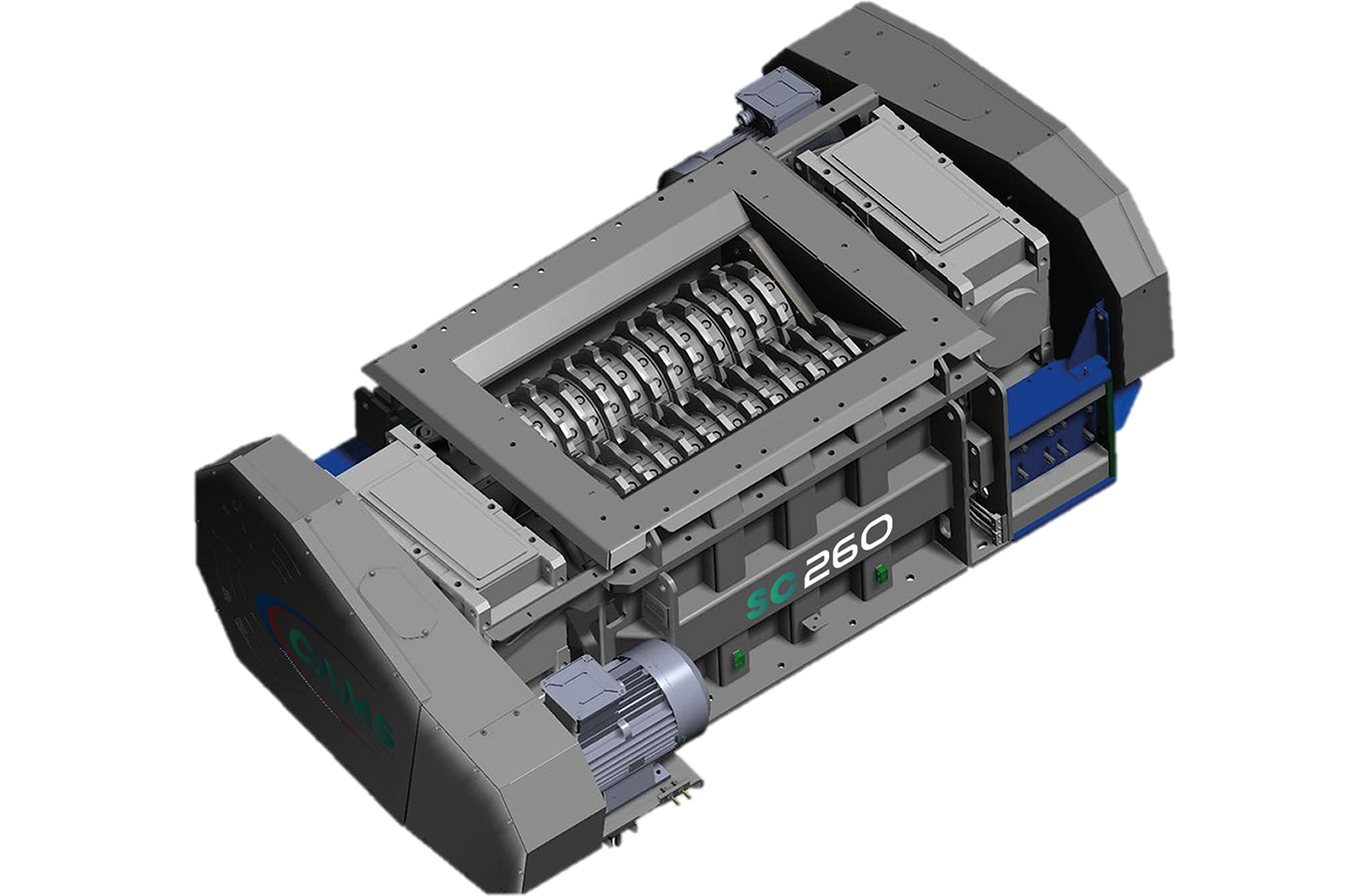

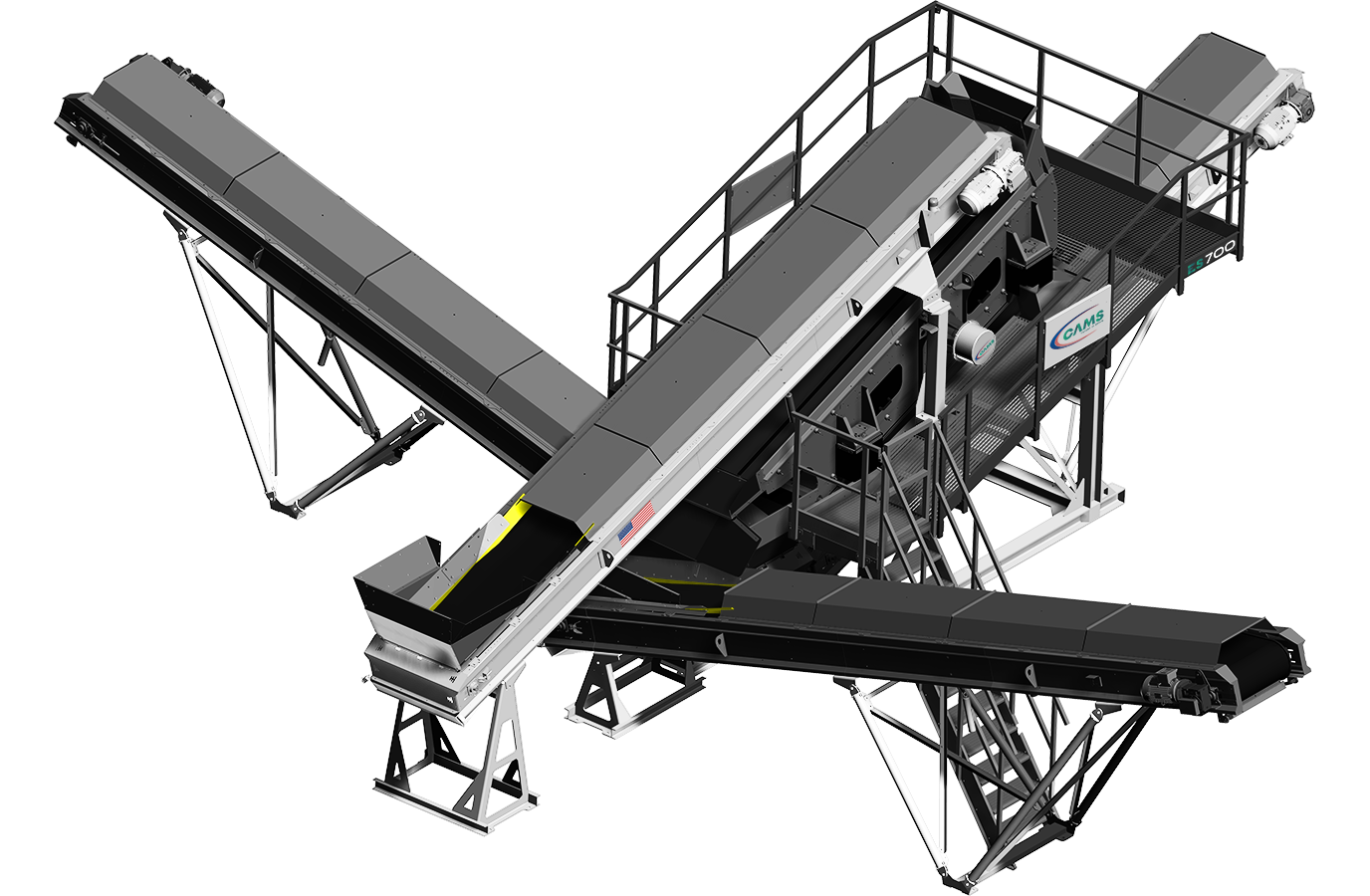

CAMSTM shredders are designed to disrupt asphalt waste without crushing it to preserve its original grading curve and bitumen content. Slow and gentle shredding technology results in fewer fines, low acoustic and dust emissions, and guarantees 100% of original bitumen content reuse, giving back recycled products with the same grading curve as the original asphalt pavimantation.

The essential source of economic efficiency.

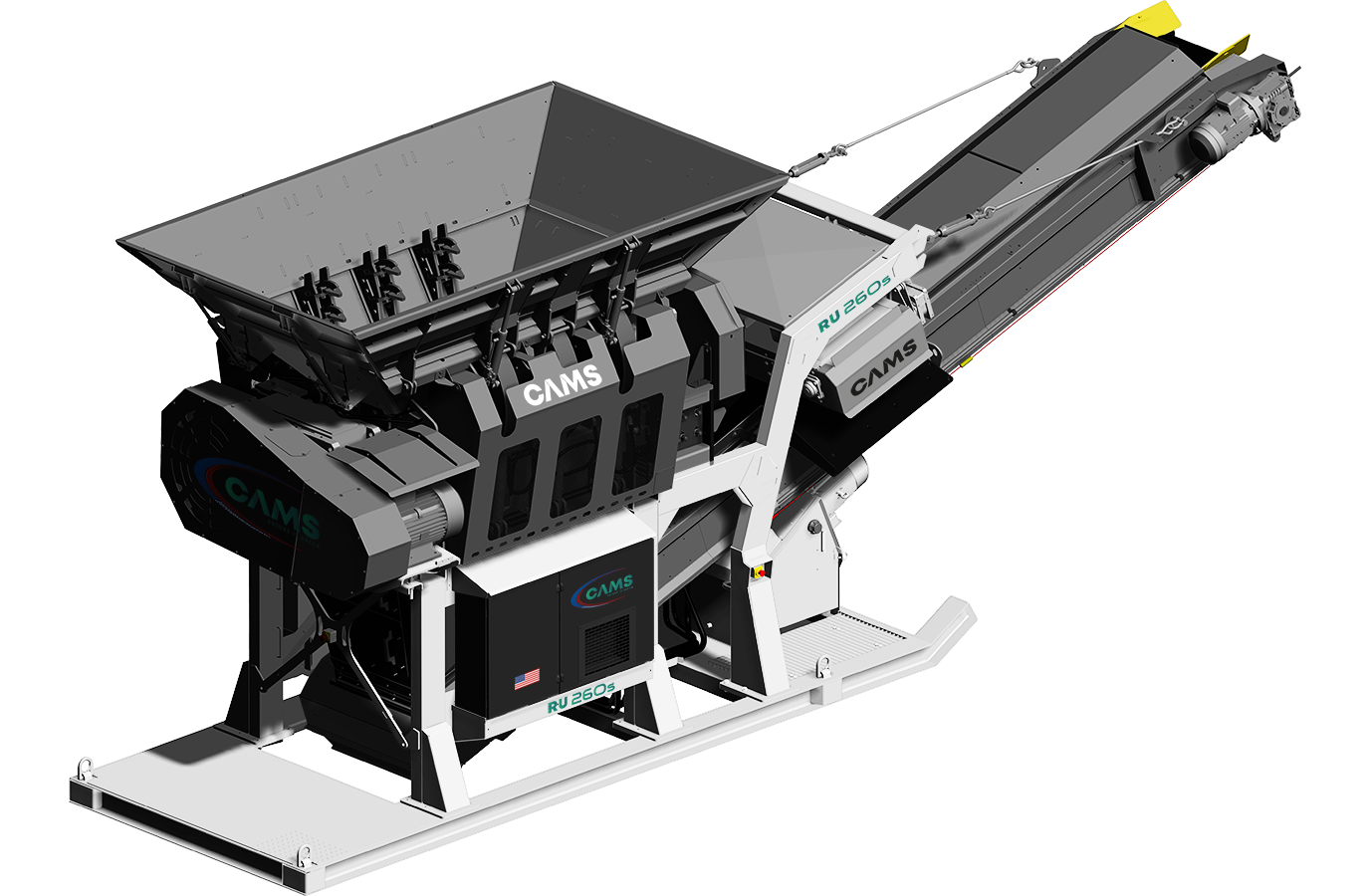

The patented system of CAMSTM hydraulic pushers, allows to load the largest asphalt slabs directly into the primary shredding unit.

The pusher pre-shred the largest chunks and keep them steady on the shafts of the primary shredder, thus making it easy for the picks to process them further.

The pushers operation can be adjusted according to the type of input material to ensure maximum efficiency.

This fully automated system can be enabled from the remote control, allowing the control directly from the excavator or the wheel loader.

Two keywords identify the CAMSTM range of asphalt recycling shredders: Power and Eco-Sustainability.

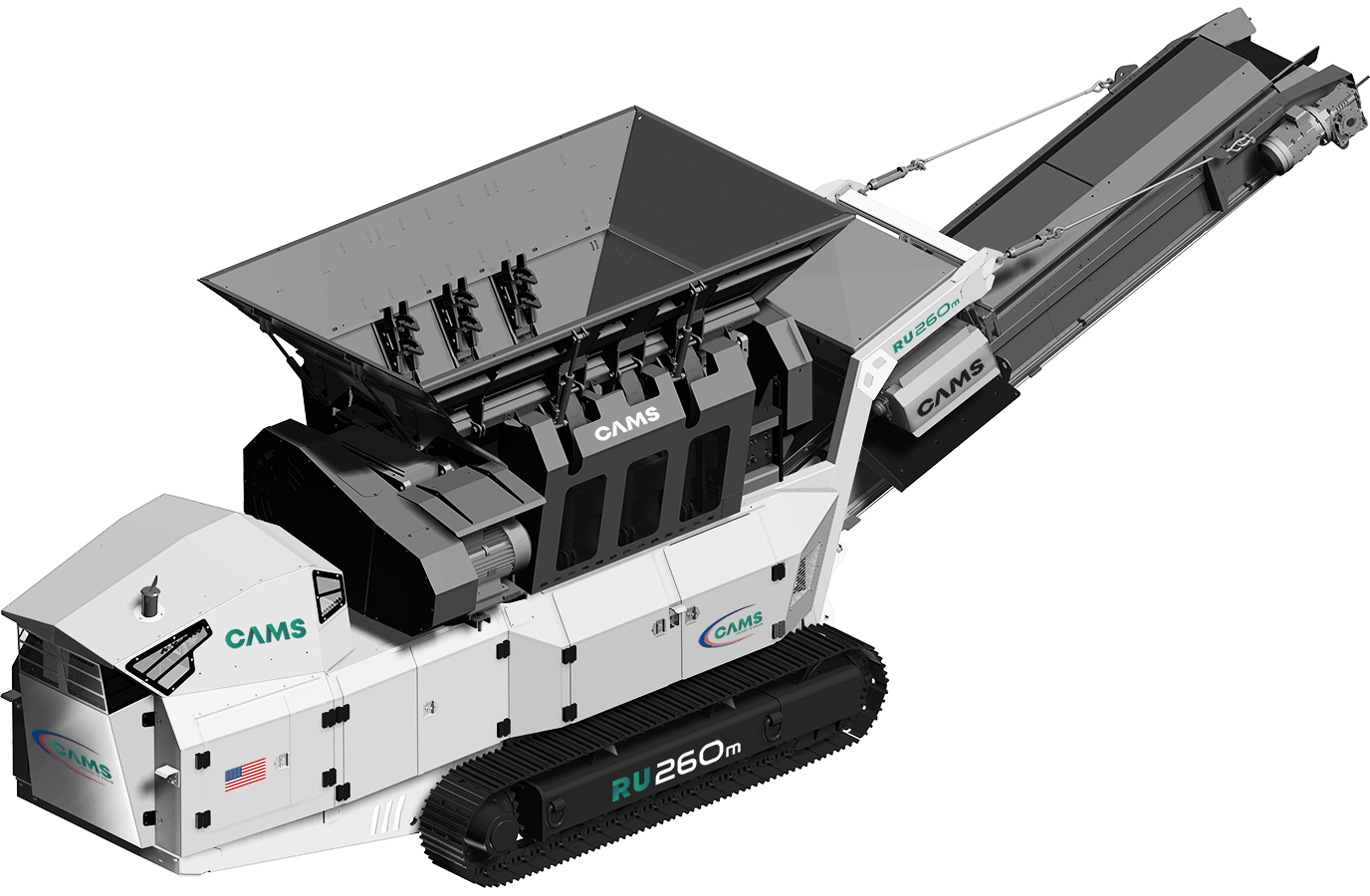

All CamsTM mobile plants are equipped with a powerful and fuelo efficient Diesel-electric drive. The Diesel engine is coupled to an alternator to produce the electrical energy necessary for all the recycling operation and make it possible for the machines to provide electrical power to the job site.

For this reason the Diesel engine operates at steady state speed at 1500 rpm, ensuring maximum torque at the lowest fuel consumption and noisy emissions.

All machines can operate in full electric mode by exploiting the electric current of the site for zero CO2 emission.

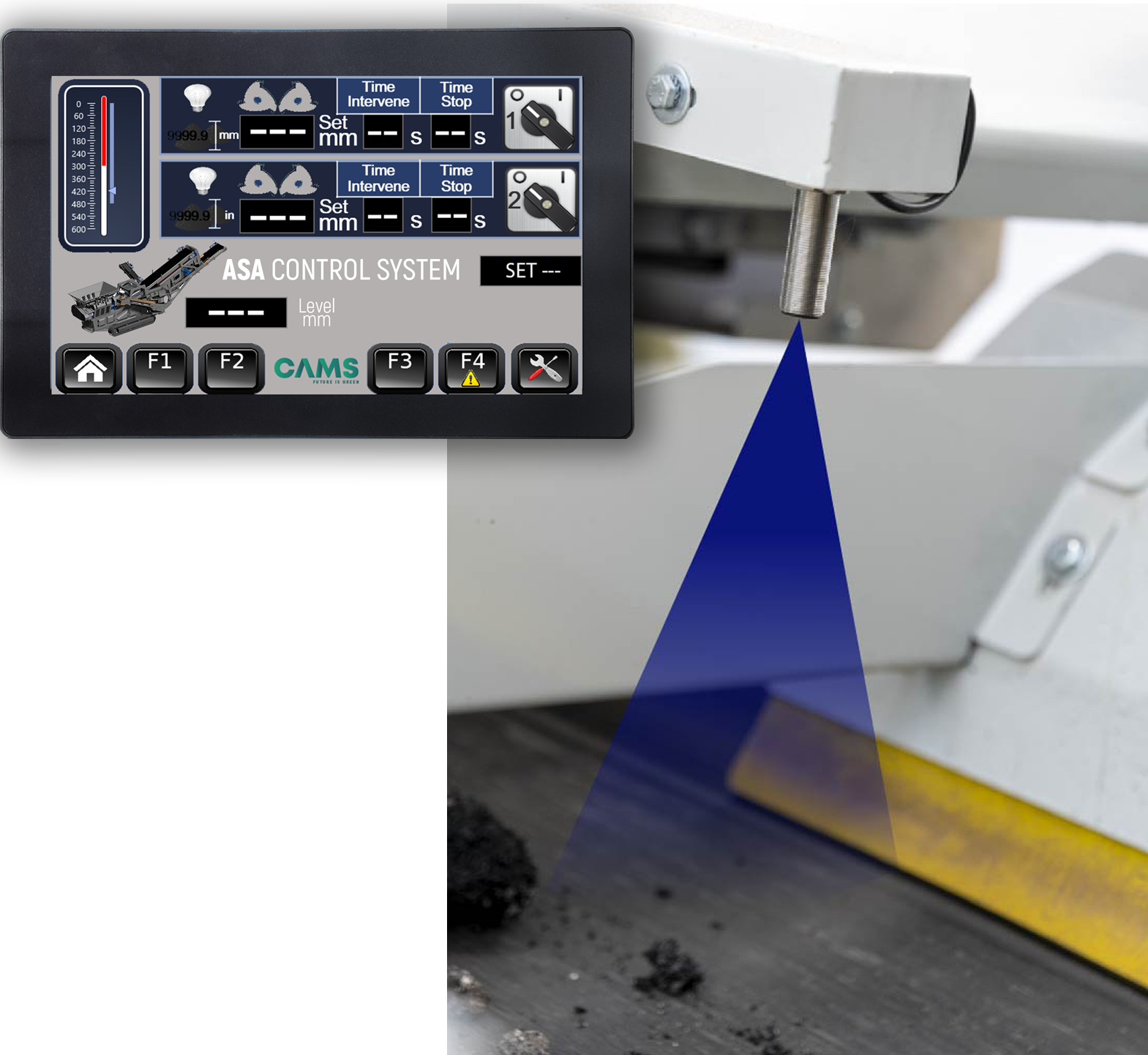

The ASA sensor detects the level of material on the main belt of your APRTM.

Depending on the amount of material, the flow throught the primary shredder is adjusted to the optimal amount.

The user of the machine has the possibility to set, throught the PLC, the maximum thresholds for the operation of the ASA system.

Throught its differential setting, the ASA system is able to adjust the operation of the primary shredder by stopping alternately one shafts or both shafts of the primary shredder with the aim of modulating the production of the machine and making the recycling process more efficient.

Maximum operational efficiency, automated.

PLC software developed by CAMSTM engineers allows the complete control of the machine, automating its production process and making its use simple and intuitive for the user.

The automatic sequences make it possible to start the recycling process with a button, while the PLC controls the operation of all the plant components

Throught the PLC system, all the machines are able to operate the recycling process in just 30 minutes.

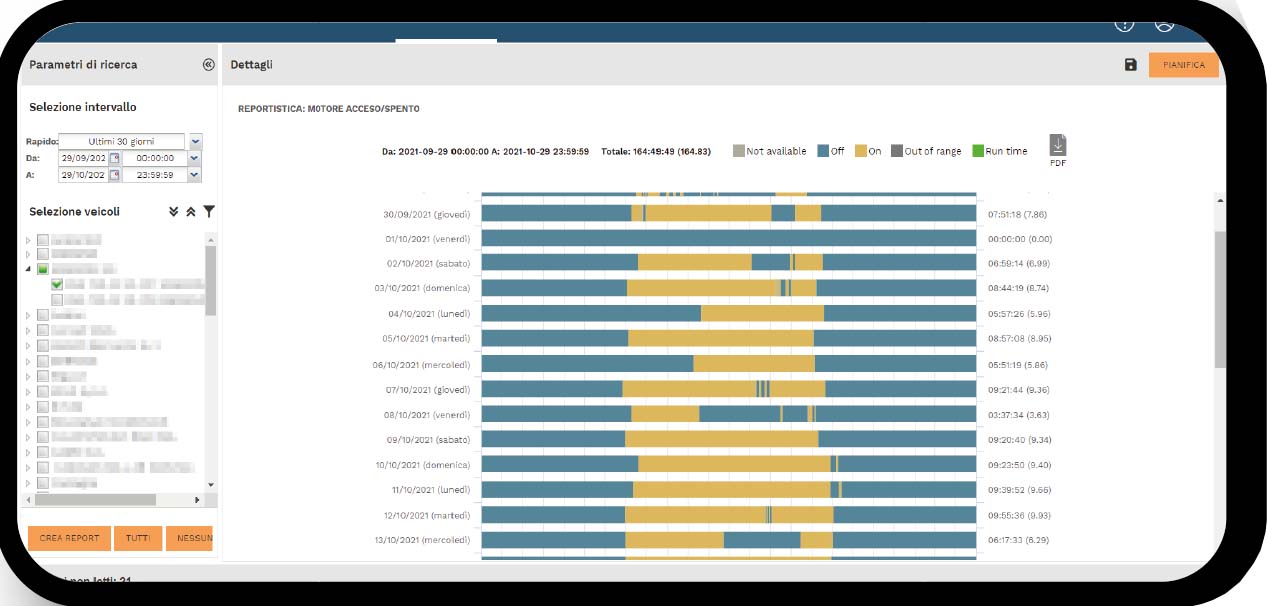

- Complete control of the mobile plant

- Customizable functions

- Components testing

- Performance control

- Remote service and GPS features

- Weighing system

- Intuitive troubleshooting guide

- Interactive PLC remote visualization

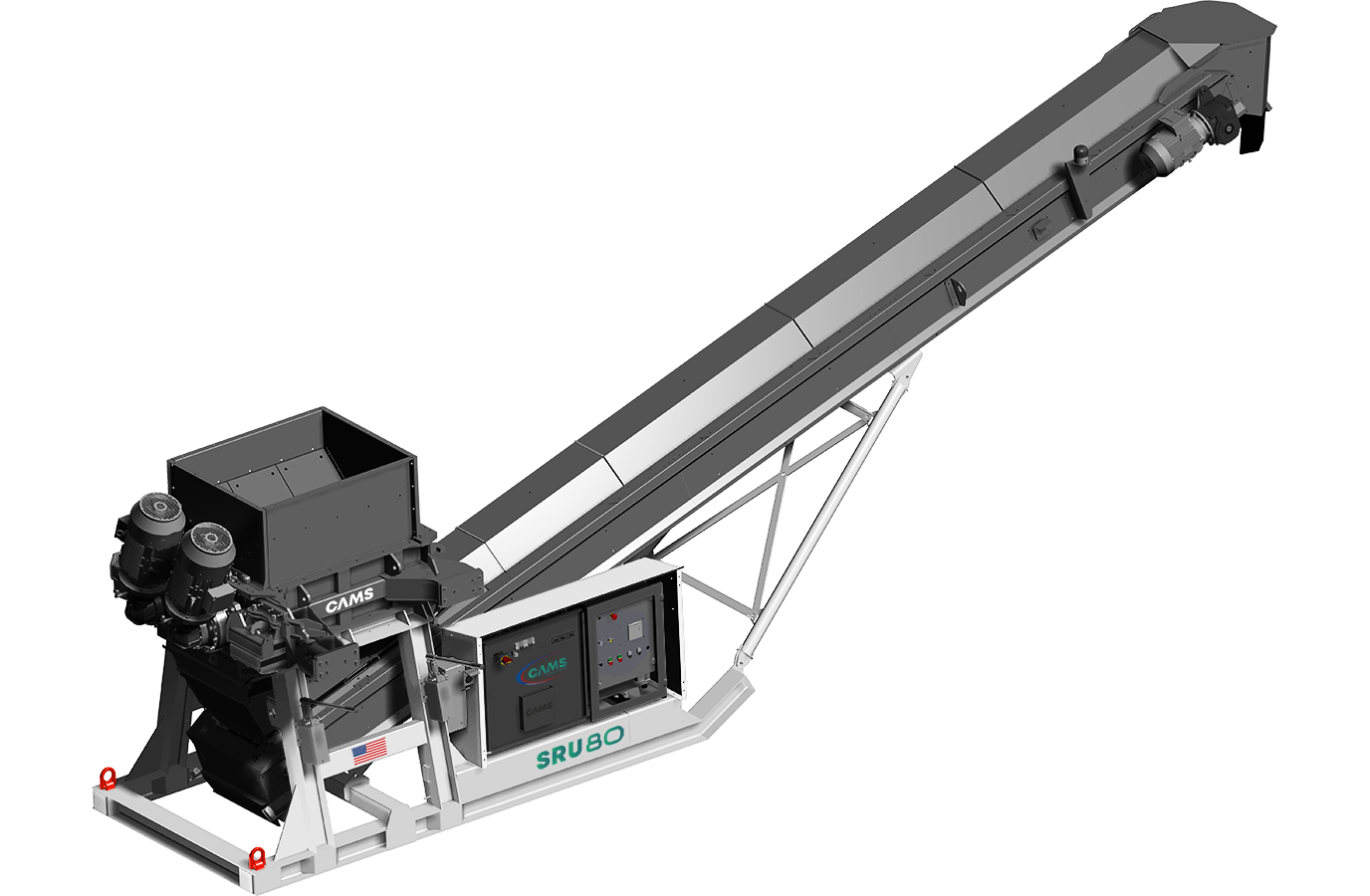

Safetly install, move and control any CAMSAMERICA shredder using the radio remote control.

Equipped with long life batteries and a wide operating range, CAMSAMERICA radio remotes grant the complete control from the excavator or the wheel loader.