SHREDDERS, NOT CRUSHERS

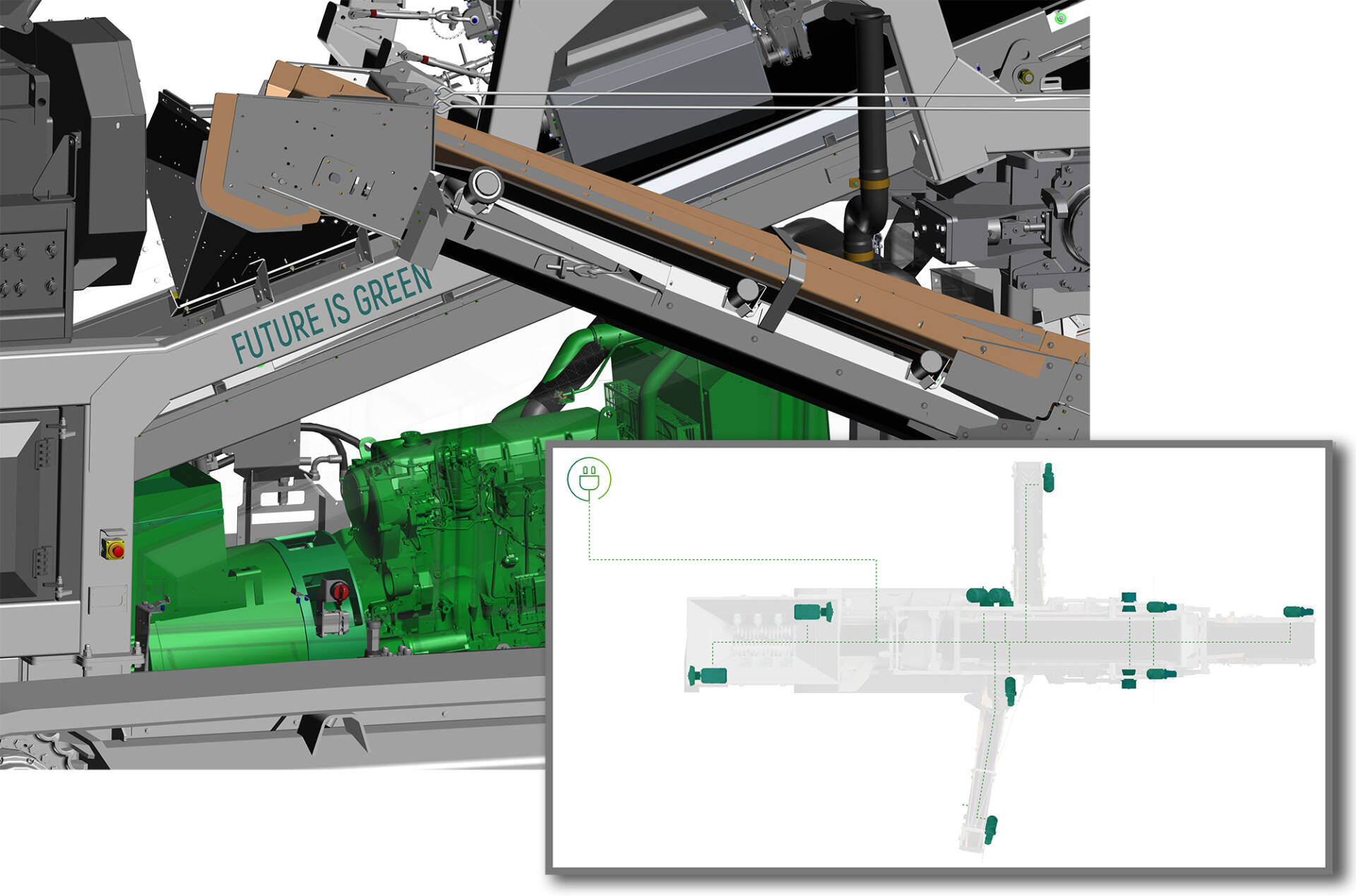

CAMS™ technology gives back several environmental advantages. Low breathable dust production, low acoustic emissions, zero soil vibration, and the opportunity to plug the shredder to the jobsite electric switch.

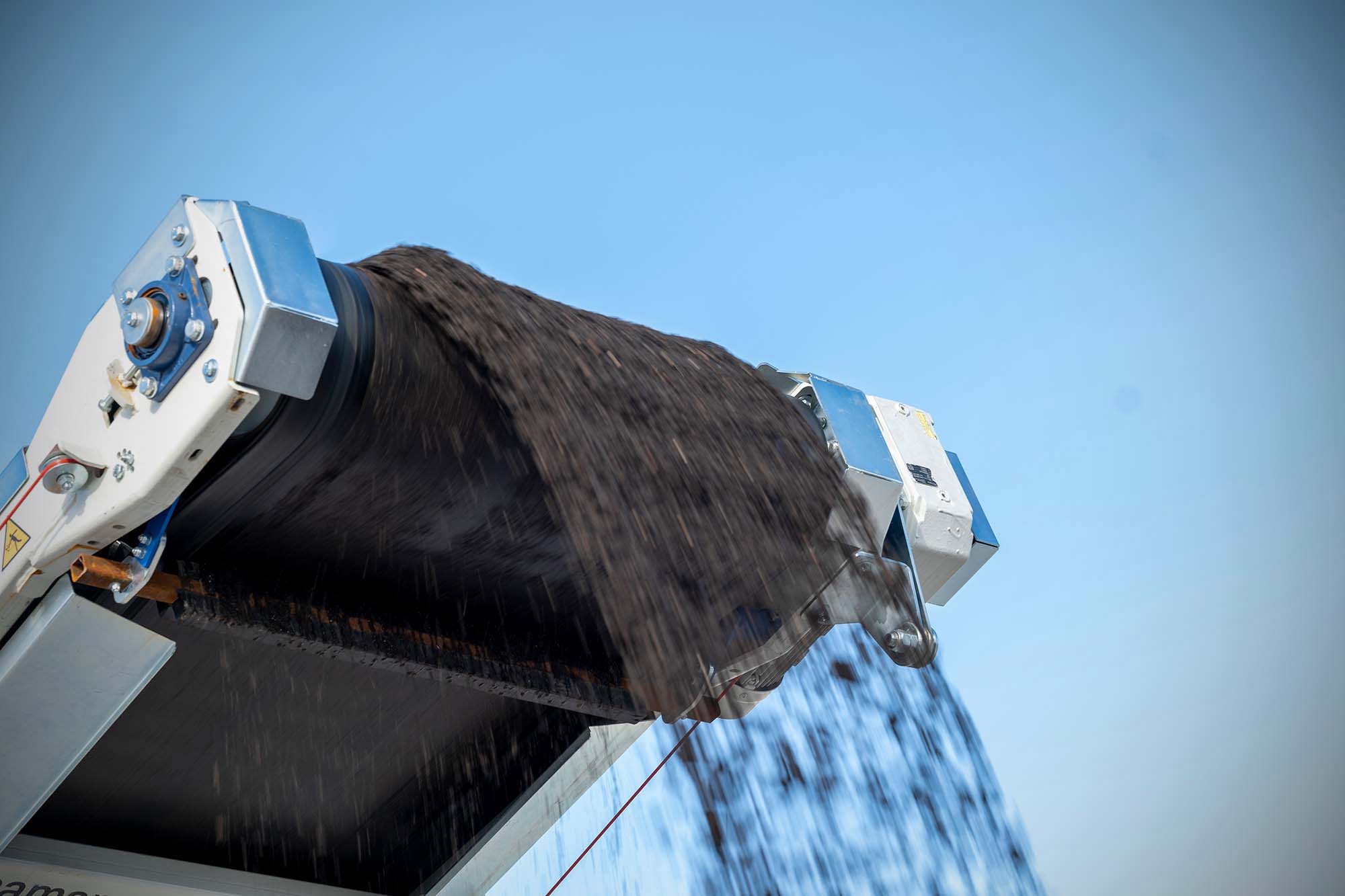

CAMS™ shredders shafts are meant to disrupt asphalt waste without crushing it to preserve its original grading curve and bitumen content. This is what makes the recycling process so efficient.

CAMS™ shredders are designed for recycling. Both the primary and secondary shredders operate according to the shear shredding principle.

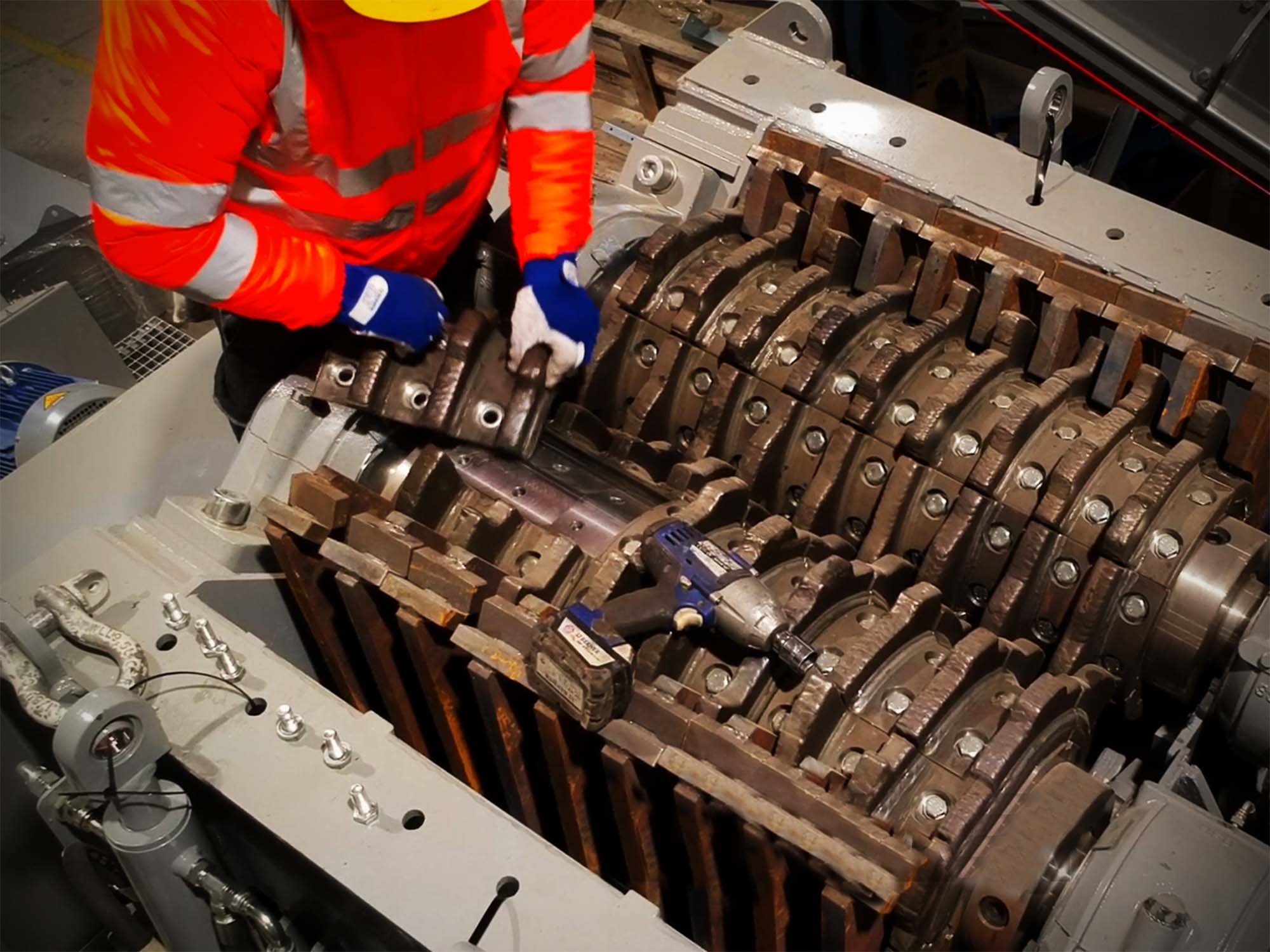

The slow rotation mechanism of CAMS™ shredders shafts significantly reduces the wearing. A patented system allows to easily replace the components without disassembling the machine.